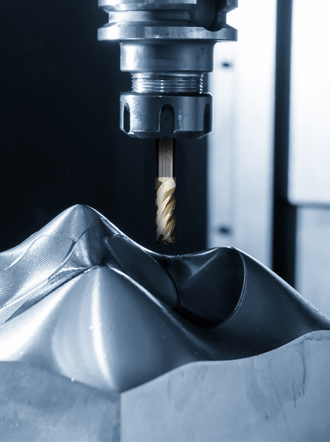

Tool Reconditioning

SCTool’s abilities are not limited to manufacturing. We take pride in our ability to service a customer’s product from inception through the life cycle of the product – cradle to grave.

Our Tool Reconditioning Capabilities

- Professional regrinding, original recoating, and high precision reconditioning of other cutting tool brands back to original specs

- CNC reconditioning of high-performance drills, reamers, end mills, and many other types of carbide, cobalt, and high-speed steel rotary cutting tools

- Upon request, expedited regrinding in case of an emergency

- Upon request, SCTool laser etches the tool each time the tool is reground to track the number of regrinds

With our Reconditioning Program, our customers save 40-75% per tool on average.

We make it easy

Place your tools in our company regrind box and we will return them to you clean, sorted, sharpened, and sized – ready to be placed in the spindle. SCTool will send you an appropriately sized box for your application.

Email us at info@sctoolcorp.com to start your reconditioning service.

Accommodating Special Requests

- Edge prep

- End work only

- Laser etch each tool’s shank for tracking the number of regrinds

- Recoating

- Cutting diameter only

- Additional modifications